01.

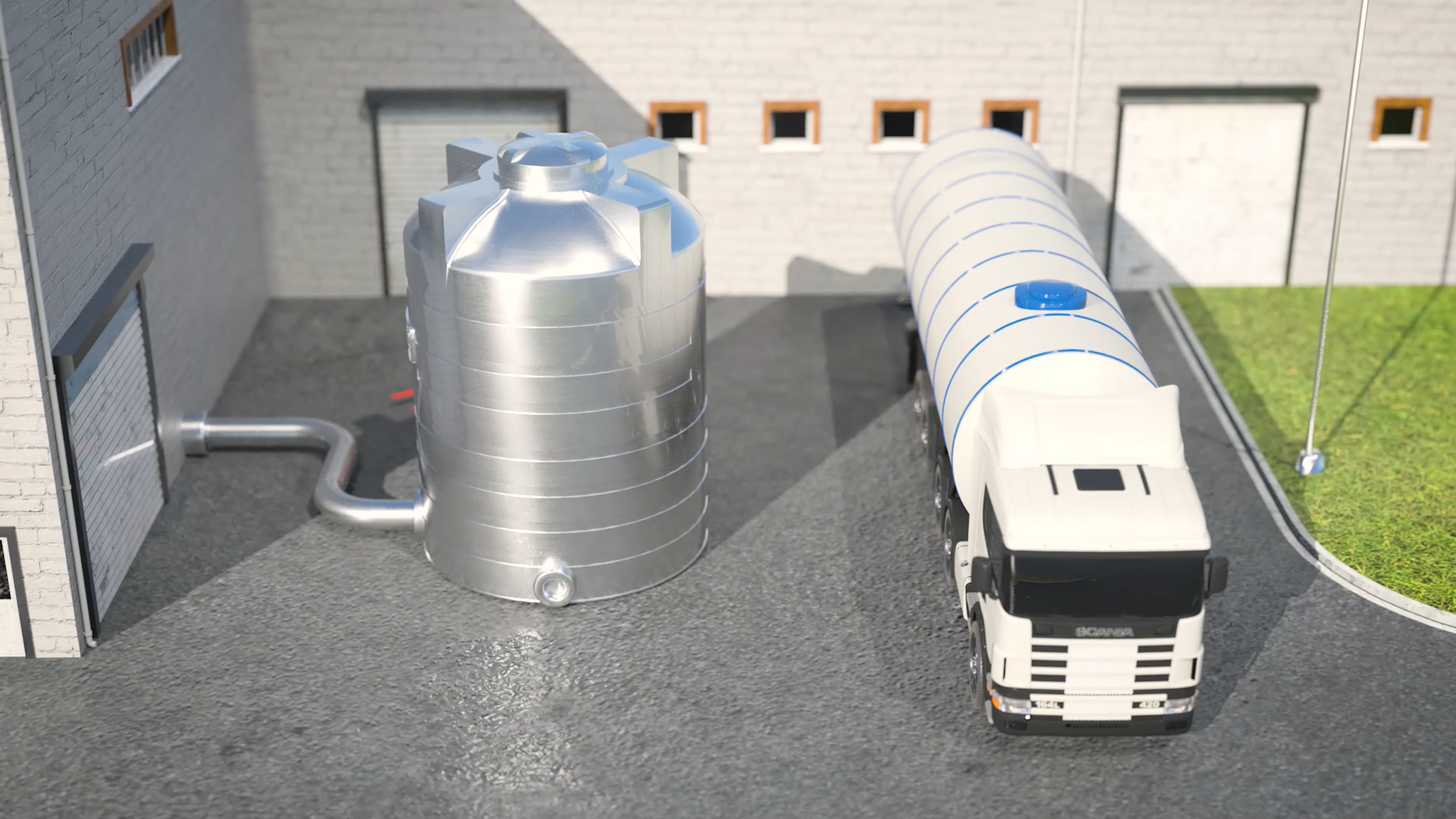

Wastewater Intake & Preprocessing

Industrial wastewater is captured and pre-treated to break down and homogenize the wastewater while removing large solids, ensuring optimal conditions for microbial activity in the next stages.

Our Solutions

Our Technology

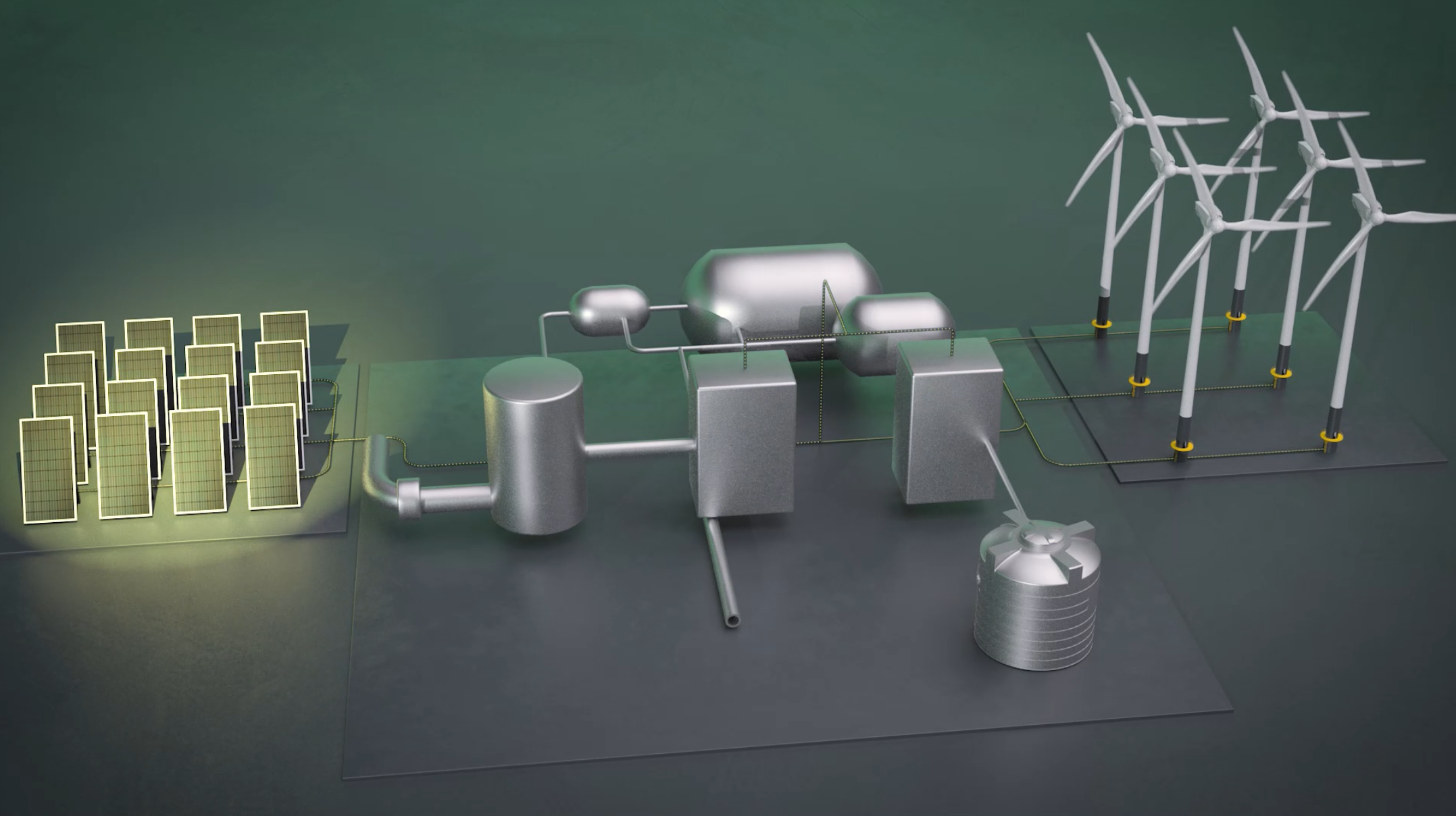

Aquature transforms industrial wastewater from a cost center into a resource recovery platform.

Our bioelectrochemical technology enables carbon-negative treatment, green chemical production, and energy recovery — helping industries cut emissions, reduce costs, and unlock circular value from even the most challenging wastewater streams.

01.

Industrial wastewater is captured and pre-treated to break down and homogenize the wastewater while removing large solids, ensuring optimal conditions for microbial activity in the next stages.

02.

Inside Aquature’s Bio-Assisted Electrolysis (BASE), specialized bacteria convert organics into electrons and green chemicals, such as hydrogen and cleaning caustic using minimal external energy input.

03.

Recovered products like hydrogen and cleaning caustic, biogas, hydrogen, and bio-acids are separated using downstream systems tailored to the customer’s needs — enabling onsite reuse or sale into green chemical value chains.

04.

The remaining treated water is clean and compliant with discharge standards or reused internally, pre-treated to break down and homogenize the wastewater while removing large solids, ensuring the support of circular water strategies and reducing dependency on freshwater sources.

Why Aquature?

Aquature enables carbon-negative wastewater treatment by converting organics into green fuels and chemicals, avoiding methane emissions and offsetting CO₂ through resource recovery — helping industries exceed net-zero targets.

In addition to clean water, Aquature recovers energy-positive, high-value chemicals like hydrogen, volatile fatty acids, and biofertilizers — turning waste into a revenue stream and enabling new circular business models.

Aquature’s modular design supports deployment from pilot to full industrial scale, with flexible configurations adapted to site size, effluent load, and industry-specific needs — no one-size-fits-all constraints.

Compared to conventional treatment and digestion systems, Aquature requires up to 82% less capex per cubic meter and reduces sludge disposal and aeration energy, cutting total OPEX significantly.

Aquature outputs water that meets reuse or discharge standards, helping industries reduce freshwater dependency, align with EU water reuse regulations, and build resilient, climate-adaptive operations.

Equipped with real-time monitoring and control, Aquature’s system can optimize performance dynamically, detect shocks early, and provide transparent data for compliance, reporting, and ESG impact tracking.

Results

At Aquature, we believe that sustainable wastewater management isn’t just an environmental imperative—it’s a strategic business advantage.

Our impact studies showcase how our solutions can impact key industries to deliver measurable results.

Where we work

01.

Aquature helps food and beverage producers turn nutrient-rich wastewater into a source valuable green chemicals that can be used onsite or sold. Our process reduces treatment costs, emissions, and waste while supporting circular production and water reuse goals.

02.

Aquature helps the biotech industry treat the waste arising after fermentation processes, reducing tankering and offsite wastewater treatment costs while creating caustic to reduce the high costs of cleaning tanks.

03.

Aquature enables farmers and agri-processors to treat their dense wastewater while recovering biofertilizers and creating reusable process water and renewable chemicals - supporting sustainable land use, water reuse, and low-carbon circular agriculture.

04.

Aquature enables pulp and paper mills to treat high-COD, fiber-laden effluents while recovering energy and green chemicals. Our system reduces sludge volumes, lowers treatment costs, and supports closed-loop water and chemical reuse in this resource-intensive industry.

Aquature goes beyond cleaning water. Unlike conventional systems that consume energy and generate sludge, our bioelectrochemical process treats wastewater while producing green chemicals and energy. This enables carbon-negative performance, cost savings, and resource recovery — unlocking circular value instead of creating waste.

Depending on the wastewater profile, Aquature can recover hydrogen, caustic, and carbondioxide. These products can be reused internally, sold into green markets, or fed into other chemical processes — creating new revenue streams and offsetting the cost of water treatment.

Aquature is built for high-strength, organic-rich wastewater. We serve sectors like food and beverage, biotech, agriculture and pulp and paper. Our modular system is tailored to fit your flow rates, effluent composition, and space limitations — with options for onsite pilots and gradual scale-up.

Aquature’s microbial electrolysis system is fully modular, making it ideal for both small pilot units and full-scale industrial deployment. Modules can be added or adjusted based on your flow and recovery goals — allowing flexibility without overhauling your existing infrastructure.

Our system is designed for plug-and-play integration with existing pretreatment or post-treatment infrastructure. We conduct site assessments, provide engineering support, and work closely with your team to align installation with regulatory standards, safety protocols, and operational targets.

We start with a free screening of your wastewater data to assess compatibility and potential recovery outputs. If aligned, we offer a pilot demonstration to validate performance on your site. This reduces risk and ensures ROI before full-scale rollout.